Leading forming machinery manufacturer

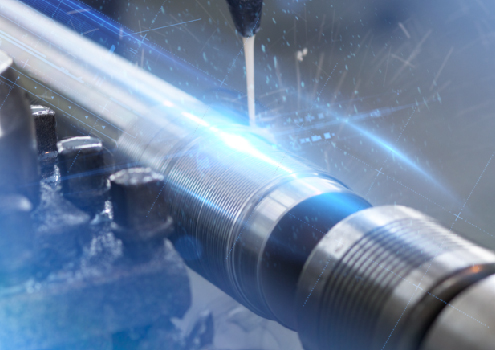

Since the 1990s, the design of metal forming machines in China has extended to custom machinery for metal roofing, wall panels and related construction metal materials. With the development of roll forming machines, cold forming technology has been applied in more fields, such as garage door panels, roof tiles, racking system columns, cable trays and any other materials that require metal profiles. Our factory was one of the first manufacturers to produce roll forming machines, after years of development, our factory has grown and enjoyed a high reputation in the roll forming line industry. We can manufacture the equipment to your satisfaction according to your requirements!

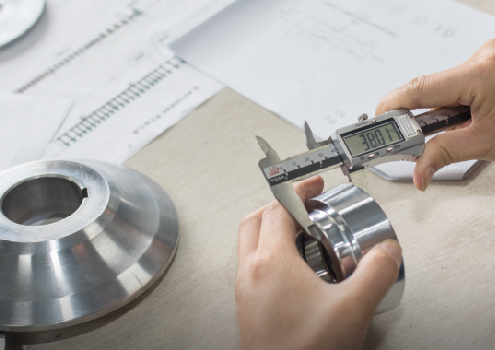

High quality components Inverter Brand: Yaskawa Electric Parts Brand: Schneider Encoder Brand: Omron Electronic valve Brand: Beijing Huade Electrical components Brand:Schneider One complete Roll former is including below parts: de-coiler, leveling system, roll forming machine main body, hydraulic cutting system, hydraulic station and controlling table. Besides these, if there are hole on the profiles, also it needs the punching system, for big thickness material profile, need the press punching system. If customer want to save human labor, the automatic stacker can be designed and added to the rollforming line. Punching machines in the rollforming lines are High efficiency coil-fed punching machines and perforation lines.

8000 ㎡

Production Area

30 +

Total Staff

2500 set

Year/Sets

15 Year

Experience

Rollformer Manufacturer

START ROLLFORM is developing and supplying metal profile roll forming machines, turnkey lines and solutions for specific applications in the high-tech sector and customers with high technical requirements. Suzhou Start Technology Co., Ltd. is a professional manufacturer of color steel tile roll forming machine, CZ Purline roll forming machine and for steel structural building light steel structures. It has the strength to design and manufacture various types of thick and thin steel plate roll forming production lines. For example, color steel plate profiled tile roll forming machine and CZ purlin roll forming machines are widely used in various large and small industrial plants, warehouses, civil and high-rise buildings. The company specializes in the production of metal roofing panel roll forming machines, metal wall panel roll forming machines, glazed tile roll forming equipment, arching roll forming machines, floor decking roll forming machines, CZ purlines roll forming machines, metal door frame roll forming machines, metal door panel equipment, rolling shutter door machines, rolling shutter door U guide rail machines, light steel keel roll forming machines, high-speed guardrails road barrier roll Forming machine, shelf racks roll forming machine, shelf panel equipment, metal silo equipment, photovoltaic support U stut equipment, seismic support equipment, metal embossing machine, shearing machine, slitting machine, rolling rotary punching equipment, hydraulic pressure of various tonnages Uncoilers, automatic stackers, and forming machines for some special-shaped profiles metal products, such as steel hoop forming punching and shearing machines, grape trellis bracket forming machines, etc.

Quality

Service

Innovation

START Mission

START Mission Our mission is very simple, to design and produce more cold-formed forming equipment that satisfies customers, let our cold-formed forming equipment spread across every country, and contribute to the urban and rural construction of each country! From de-coilerto profile cutting, Metal Rollforming Systems is your trusted partner, it is simple operating, but bring you the excellent metal products. Metal Rollforming Systems aims to be your ‘one-stop shop’ for all your metal profiles rollforming needs, allowing our customers to save time and money when purchasing a rollformer. In order to speed up the rollforming, high technology is updated, the tracking punching, tracking cutting, heavy duty gear box transmission, double layer designing for sheet panel, double production line for steel framing profiles, Automatic linear adjusting rollfoers which can produce a range of sizes of profiles. Also for customers who want to save cost, we design the economical machine for adjusting size by changing certain small parts on the rollers and shafts.